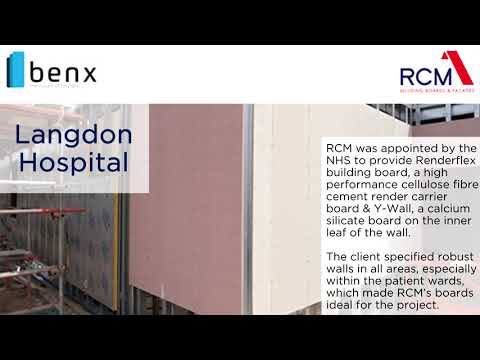

RCM Y-wall can be used as an external sheathing board on all structure where a fire rating is required including those greater than 18m in height, where a structure is over 18m in height RCM Y-wall should be used from ground level all the way up the structure.

Technical Request Form

For Technical Service or Product Support please file a technical request using our support form or contact your local representative.

Technical Request Form